While profitability is essential in Food and Beverage manufacturing, food safety is mission-critical. No food manufacturing executive wants that dreaded Monday morning call from the FDA announcing that over the weekend, a salmonella outbreak traced to their product has resulted in 7 hospitalizations, 2 of which are in critical condition.

The Food and Beverage business prioritizes food safety and compliance to provide consumers with high-quality products. As the industry’s focus on health and severe laws grows, food and beverage firms must implement robust procedures to assure compliance.

The Food and Drug Administration and the U.S. Department of Agriculture announced 313 food recalls (impacting products that were still on sale) and alerts (involving products no longer on sale but may be in consumers’ homes) last year, an 8% increase from 2022 and the highest number since the COVID pandemic began in 2020, according to a report released Thursday by the nonprofit U.S. Public Research Interest Group Education Fund.

Contaminated food resulted in six deaths and over 1,100 illnesses last year, though the researchers suspect there were more illnesses since most people recover from food poisoning without medical attention.

Source: Report Finds 2023 Had Highest Food Recall Levels Since Start Of COVID-19 Pandemic (forbes.com)

Enterprise Resource Planning (ERP) systems, like DynamicsFoodERP from Liberty Grove, powered by Microsoft Dynamics 365, can help meet and maintain these standards. ERP systems offer a comprehensive solution for simplifying procedures and guaranteeing compliance with food safety laws. By combining all internal company capabilities and methods into one solution, ERP solutions improve operational efficiency, reduce risks and errors, and increase compliance and visibility across the supply chain.

Understanding Food Safety Regulations

The Food and Drug Administration (FDA) establishes regulations and guidelines governing food safety in the United States. These standards cover proper manufacturing procedures, labeling requirements, allergy management, and hazard analysis. For example, the Food Safety Modernization Act (FSMA) promotes preventative measures, risk assessments, and control strategies to avoid foodborne illness. Regulatory compliance is critical for protecting consumers, preserving a healthy brand reputation, and avoiding costly penalties.

Modern ERP systems provide a comprehensive solution to help Food and Beverage manufacturers satisfy regulatory demands. They address supply chain complexity, varying ingredient quality, and human record-keeping processes. ERP systems offer an integrated approach to regulatory compliance by automating operations, providing real-time data visibility, and maintaining traceability throughout the production cycle.

Food and Beverage manufacturers often face significant challenges in meeting regulatory standards. However, modern ERP systems offer comprehensive solutions to these challenges. They effectively manage the complexity of supply chains, variations in ingredient quality, and manual record-keeping processes.

With an industry-specific ERP solution, manufacturers can automate processes, enable real-time visibility, and ensure product traceability throughout the food production cycle – an integrated approach to regulatory compliance.

ERP Features for Food Safety and Compliance

Traceability and Lot Tracking

ERP systems record and track comprehensive product information, such as lot numbers, expiry dates, and supplier details. ERP systems allow for speedy traceability during product recalls or safety concerns by assigning unique identifiers to each batch. In a quality issue, manufacturers can promptly identify the affected batches, establish the leading cause, and implement corrective activities, reducing the possible impact on consumers and the company’s reputation.

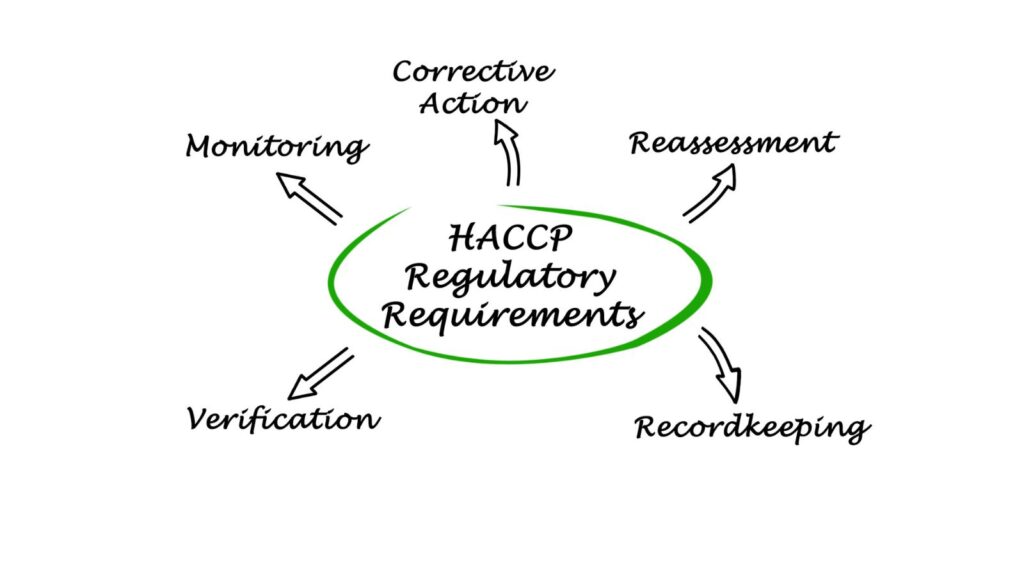

Integration of HACCP (Hazard Analysis and Critical Control Points) Principles

A modern ERP system includes HACCP concepts for more than just compliance. The technology incorporates a proactive approach to food safety, identifying critical control points in the production process and eliminating or lowering them to acceptable levels. Real-time monitoring of critical control points, alerts, and notifications for deviations enables firms to fix issues quickly and deliver safe products to customers.

Supplier Management and Compliance

ERP systems are vital in managing supplier relationships and ensuring compliance with FDA regulations. Food and Beverage manufacturers can track supplier qualifications, certifications, and performance metrics through integrated supplier management modules. An ERP ensures that suppliers meet the necessary standards for ingredient sourcing and safety. By maintaining accurate supplier information within the ERP system, businesses can quickly identify and address compliance issues, reducing the risk of non-compliant materials entering the production process.

Allergen Management

Allergen control is crucial for food safety because allergenic substances can pose severe dangers to people with allergies or sensitivities. ERP solutions enable organizations to manage allergens throughout their supply chain better. Food and Beverage companies can establish adequate segregation and cleaning methods to avoid cross-contamination by identifying and tracking allergy ingredients throughout manufacturing. ERP systems’ automated alerts and notifications provide rapid risk resolution, allowing businesses to meet allergy labeling standards while protecting customer protection.

Improved Product Quality and Safety

ERP systems are essential in improving control over production operations and ingredient procurement. By adding food safety procedures to their operations, businesses enhance product quality and safety. Real-time data visibility helps firms recognize and manage quality concerns early, assuring safe and high-quality products for consumers. This quick discovery and resolution of quality issues reduces product recalls and associated expenses, preserving the company’s brand and consumer trust.

Streamlined Compliance Processes

ERP systems make data gathering and reporting more accessible, lowering the administrative load associated with regulatory compliance. They offer standardized workflows for gathering and evaluating data needed for inspections and audits. Automated report production guarantees that firms may efficiently present required paperwork to regulatory authorities, speeding compliance processes and lowering the risk of noncompliance penalties. ERP systems reduce human errors and paperwork, increasing compliance accuracy and efficiency.

Enhanced Transparency and Visibility

ERP solutions enable real-time access to vital data and insights throughout the supply chain. Businesses can generate comprehensive reports and analytics to improve food safety and compliance decision-making. Food and beverage firms can improve their food safety practices by monitoring key performance metrics and evaluating data patterns. ERP systems provide enhanced transparency and visibility to enterprises, giving them a sense of control over their operations and compliance.

Ready to be on the Right Side of Food Safety?

Whether you’re considering upgrading your ERP or implementing a system for the first time, the Liberty Grove team of ERP consultants can guide you through each step for a smooth ERP solution. Liberty Grove’s DynamicsFoodERP is powered by Microsoft Dynamics 365 and can help your team simplify procedures, ensure compliance with food production laws, and guarantee your food safety record.

Contact Liberty Grove for a complimentary consultation on how a Food and Beverage ERP can help you monitor product quality and protect your customers and your reputation.

Related reading:

Modern ERP for Food & Beverage: Enhancing Traceability & Recall

Compliance Matters: 8 Ways ERP Can Help Food and Beverage Manufacturers

5 Ways an ERP Helps with Compliance in Manufacturing

About the author

Liberty Grove Software is an established Microsoft Partner that focuses on providing customers with sales, service, and support for Microsoft Dynamics 365 Business Central/NAV solutions and training and upgrades.

Liberty Grove Software helps manufacturing firms compete by automating tedious operations with Microsoft technologies. Our extensive manufacturing knowledge has established us as the preferred Microsoft partner for assisting mid-sized manufacturers in increasing production.

Over more than 25 years, Liberty Grove has assisted hundreds of customers with businesses ranging from small to mid-sized to Microsoft Partners in implementing, training, customization, and upgrading Microsoft Dynamics ERP solutions.

The organization is one of only a few companies worldwide that Microsoft recognizes as qualified to provide Business Central/NAV Upgrade Service Centers.